Additive manufacturing faster and better

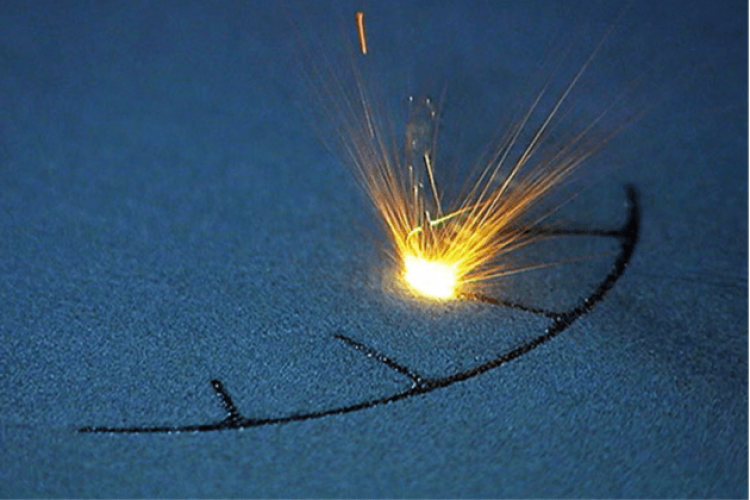

Advanced manufacturing technologies like additive manufacturing offer never before seen design and production freedoms. One example are laser powder bed fusion (LPBF) 3D printers that allow the printing of metal parts from metal powders. Due to the fact that the metal powder is welded in small portions using laser light, the physical properties can be altered for each part of the print by fine-tuning the process parameters on the printers. This allows for building parts that would not be possible with traditional manufacturing methods. However, it also makes the development of printing processes much more complicated. Additionally, to compete with conventional manufacturing methods LPBF manufacturing processes have to become more reliable and much faster.

Ensuring fast printing of high-quality parts

To assure high quality, but also fast prints we supported an LPBF printer manufacturer in the development of printer parameters for stainless steel (S.S 316L) material. The aim of the project was to increase the build rate and keep the density and mechanical properties of the printed object constant or better. The company already had existing printing parameters that could achieve a density of around 99.9% of the density of stainless steel, which is considered a high-quality print. These printer parameters had a build rate of 6.8 mm³/s at 60 μm layer thickness, which is considered the industry standard. Using their existing R&D data as a starting point, the machine manufacturer conducted 5 print jobs, with 20 test objects in each print job. During the test the hatch distance, laser power, and scan speed were varied, and all other parameters were kept constant. The layer thickness was kept constant at 60 μm. The parameter sets for each test object were suggested by the xT SAAM platform, were then printed, and tested in an external laboratory and the results were fed back into the xT SAAM platform before generating the next 20 samples.

Amazing results in only 5 prints

Over the course of the 5 print jobs, an improvement of the printing results for each upcoming print job could be noticed. In fact, in print job No. 5 all of the suggested printer parameters reached build rates of above 8 mm³/s and all print jobs reached densities of above 99.6%, with 14 of the 20 samples reached densities above 99.9%. Taking into account that the goal was to print with above 99.9% relative density, the two best samples reached a build rate of 9.2 mm³/s and 8.6 mm³/s with a density of 99.91% and 99.95% respectively, which is a 35% or 26% increase in build rate compared to the initial parameters. Most importantly, all developed parameter sets were vastly different from each other. This variety of parameter sets allows switching between parameter sets to give e.g. higher production stability.

Predictive models

Additionally to the optimized results, we were able to develop a predictive model that could reliably predict the part density given a parameter set and using the existing data we could generate parameter sets with different Pareto optimality, e.g. even higher build rate with reduced part density, with only 1-2 print jobs.

Main benefits

The project showed that our xT SAAM platform helps to reduce R&D efforts and increases part quality and/or production speed compared to currently used methods such as Design of Experiments (DoE) or one-factor-at-a-time (OFAT). Additionally, we could show that our xT SAAM platform can be used with minimal training. This allows the printer manufacturer to let new employees work with our platform and achieve great results from day one. Additionally, xT SAAM can learn from existing data sets. This means that entering existing data into xT SAAM experimental runs can be further reduced.

Exponential Technologies Ltd. (xT)

xT is an experienced player in the application of artificial intelligence (AI) and machine learning (ML) in industrial markets. In particular, xT has a track record of delivering world-class software products in the field of industrial R&D. Combining their experience with AI/ML technologies and their knowledge of the AM market, xT is ready to gradually turn the promise of “first time right” into reality.